Services

Facility Services and Capabilities

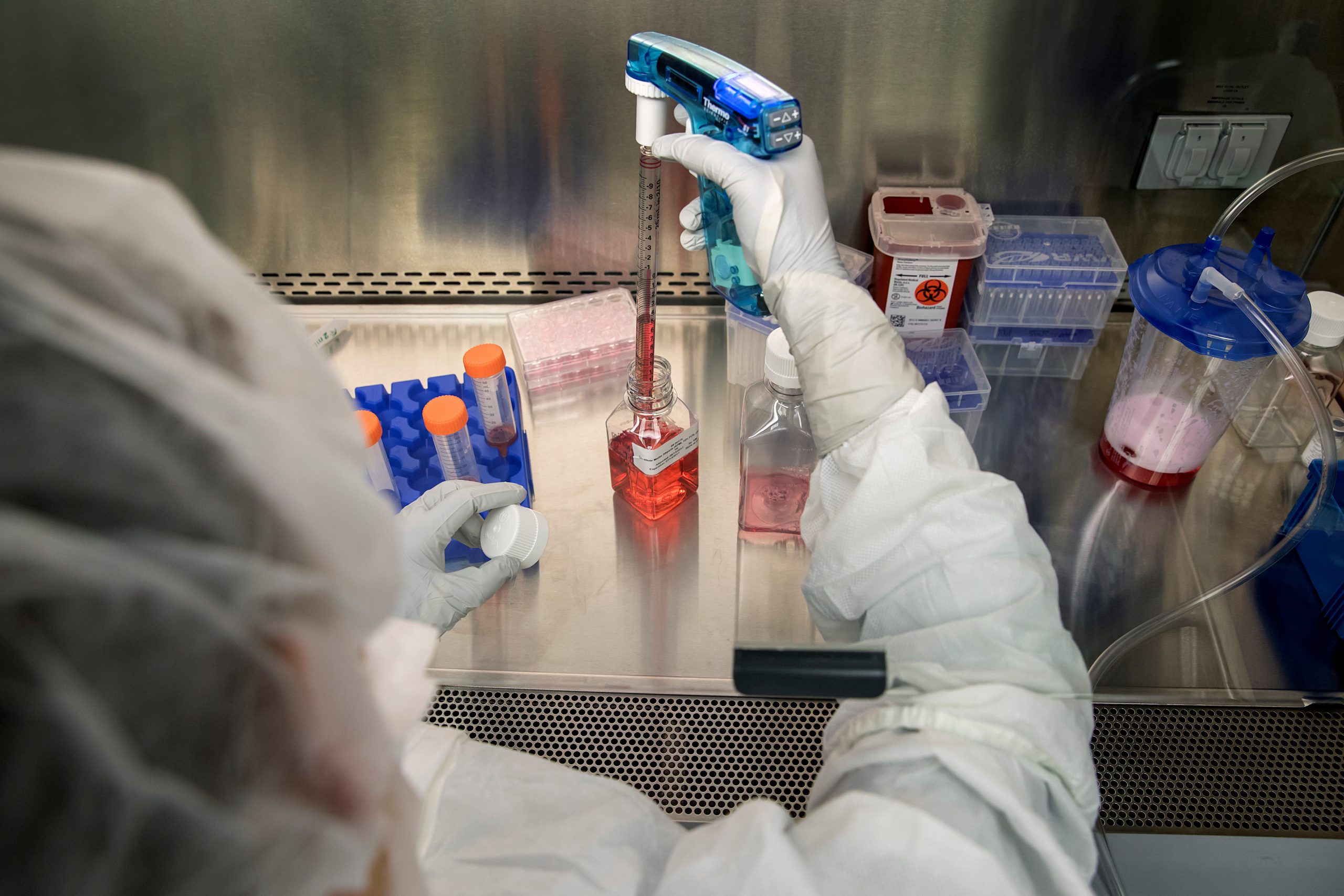

The Advanced Cellular Therapeutics (ACT) Facility was created to support clinical trials requiring human cellular therapy products at UNC Lineberger Comprehensive Cancer Center.

Members of the UNC Lineberger Clinical Immunotherapy Program are founding clients of the facility. The ACT Facility is also available as a core resource for other members of the UNC community.

Learn more about the UNC Lineberger Clinical Immunotherapy Program

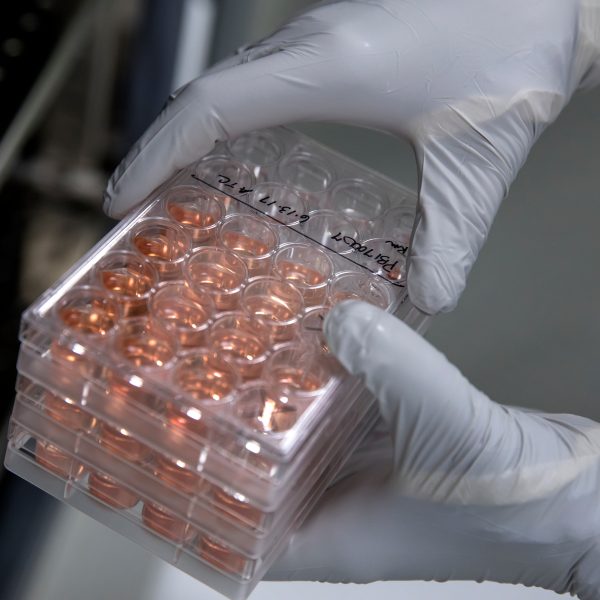

Cellular products

Good Manufacturing Practices

In addition to its ISO 7 environmental rating, the facility provides the required infrastructure (staff training, documentation, monitoring, quality program, etc.) to meet requirements. Manufacturing follows formal standard operating procedures. Each activity is documented using worksheets and batch records, which record all equipment, reagents and disposables used, together with information on calibration dates, lot numbers, expiration dates and manufacturers.

Enabling materials, such as novel retroviral vectors, required for studies are also produced within the ACT Facility following cGMP requirements. Close collaborative efforts between investigators and the ACT Facility allow rapid translation of novel developments from the pre-clinical to clinical trial applications.

Documentation

The product is released for clinical use by means of a Certificate of Analysis, which details the results of required testing. Released products are issued for use under written physician orders.

Records of all infusions, adverse reactions and subsequent tests are maintained with the product batch record. In addition, all records pertaining to environmental monitoring, facility and equipment cleaning, staff training, and deviations are maintained by QA as part of GMP documentation.